Overview

You need more than a standard oil and filter to extend engine life and time between oil changes. Particularly with the post 2009 engines  having greater emission standards and while operating at higher temperatures, with much higher rates of contaminations. Standard oil filters are ‘full-flow’, meaning they filter ‘all’ the oil that enters the fine tolerances of the engine in a single pass. These filters are generally rated at 25 microns and are designed to pass high volumes of oil at high flow rates, limiting their ability to remove high volumes of ‘ultra-fine’ particles 1-15 microns in size (such as soot/carbon). These ultra-fine particles account for the majority of contamination associated with engine wear. In addition, full-flow filters do not efficiently remove the water produced in the combustion process. This causes the formation of acids in the oil, accelerating the depletion of additives, and increases corrosive action within the engine. Full flow filters alone cannot keep oil constantly clean, reduce engine wear or prolong oil.

having greater emission standards and while operating at higher temperatures, with much higher rates of contaminations. Standard oil filters are ‘full-flow’, meaning they filter ‘all’ the oil that enters the fine tolerances of the engine in a single pass. These filters are generally rated at 25 microns and are designed to pass high volumes of oil at high flow rates, limiting their ability to remove high volumes of ‘ultra-fine’ particles 1-15 microns in size (such as soot/carbon). These ultra-fine particles account for the majority of contamination associated with engine wear. In addition, full-flow filters do not efficiently remove the water produced in the combustion process. This causes the formation of acids in the oil, accelerating the depletion of additives, and increases corrosive action within the engine. Full flow filters alone cannot keep oil constantly clean, reduce engine wear or prolong oil.

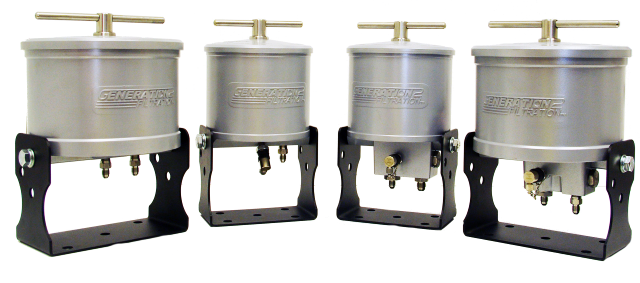

Generation 2™ ‘bypass’ filtration has the ability to polish small volumes of oil at slow flow rates, down to 1 micron, through the precision wound multi-ply ‘axial-flow’ cellulose element. This removes ultra-fine contamination and water normally missed by standard full-flow filters. With 4 stages of filtration, Generation 2™ elements are designed to meet the contamination levels associated with the new generation of engines equipped with sophisticated emission control hardware, including all types of Exhaust Gas Recirculator’s (EGR’s), diesel particulate filters (DPF) and ACERT technology. With the G2F’s ability to work efficiently in these highly contaminated engines, G2F elements have an added advantage when installed on pre 2010 engines.

Generation 2™ ‘bypass’ filtration has the ability to polish small volumes of oil at slow flow rates, down to 1 micron, through the precision wound multi-ply ‘axial-flow’ cellulose element. This removes ultra-fine contamination and water normally missed by standard full-flow filters. With 4 stages of filtration, Generation 2™ elements are designed to meet the contamination levels associated with the new generation of engines equipped with sophisticated emission control hardware, including all types of Exhaust Gas Recirculator’s (EGR’s), diesel particulate filters (DPF) and ACERT technology. With the G2F’s ability to work efficiently in these highly contaminated engines, G2F elements have an added advantage when installed on pre 2010 engines.