How It Works

The oil under high pressure (up to 4,569 PSI/315 Bar) enters the inlet at the bottom of the unit, travels up into the ‘Integrated Pressure Reduction Valve’, moves up the centre core of the G2F Element at 43.5 PSI/3 Bar, before passing down through the 4-stages of micro-depth filtration. The oil is filtered down to 1 micron then discharged from the outlet of the unit, the polished oil is then returned to the oil reservoir at atmospheric pressure. The G2F Element is to be changed at regular intervals, determined by the rate of contamination produced by the system, and the environment it is operating in. Oil analysis with a ISO particle count is recommended to monitor oil contamination levels, allowing one to meet and exceed targeted oil cleanliness levels.

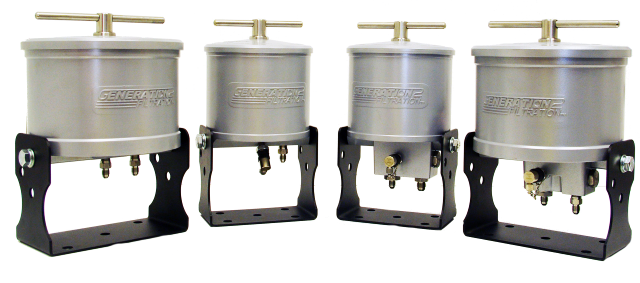

T-handle (A) – permits easy lid removal and element replacement

O-Rings (B)

Lid Ejection System (C) – automatically separates the lid from the canister

Stage 1 (D) – Surface Filtration

Stage 2 (E) – Depth Filtration

Stage 3 (F) – Pressured Micro-Depth Filtration

Stage 4 (G) – Migrating Particle Filtration

Oil Spike Suppressor (H)

Machine Sealed Edges (I)

Element Support Grill (J)

Integrated Pressure Reduction Valve (K)

Oil Sample Test Point (optional) (L)

Inlet Pressure Port (M)

Outlet Drain Port (N)

Universal Mounting Bracket (O)

YOU CHANGE YOUR OIL NOT BECAUSE YOU WANT TO…BUT BECAUSE YOU HAVE TO!

UNTIL NOW!