Explanation

What Happens During The Water Glycol Process?

Water Glycol has many critical functions. The fluid is used to transmit power, lubricate, seal and transfer heat. As it is used and reused it begins to absorb contaminants such as chips, fines, and bacteria. As these contaminants build up and pass through the hydraulic system, problems will start to occur. Valves will start to leak, orifices and ports will get blocked, seals will start to leak and components will fail. All of this will result in costly downtime and productivity loss.

Water Glycol has many critical functions. The fluid is used to transmit power, lubricate, seal and transfer heat. As it is used and reused it begins to absorb contaminants such as chips, fines, and bacteria. As these contaminants build up and pass through the hydraulic system, problems will start to occur. Valves will start to leak, orifices and ports will get blocked, seals will start to leak and components will fail. All of this will result in costly downtime and productivity loss.

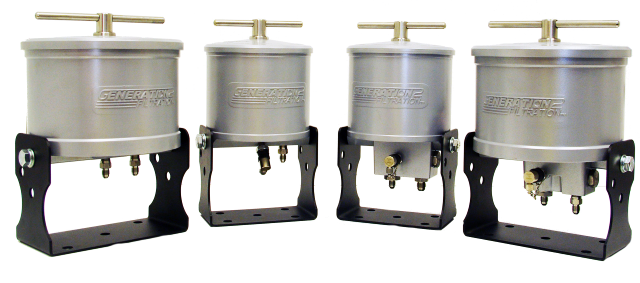

Solution: Generation 2 Filtration™ Systems

Particles and contamination does not mean that the water glycol must be disposed of and replaced. Through multi-pass filtration, the particulate and contamination can be removed from the water glycol and thus the life of the fluid can be increased. Using a GENERATION 2 FILTRATION™ system will prolong drain intervals, increase production “up time”, decrease costly “down time” and helping you environmentally while adding significant savings to your “Bottom Line” by utilizing our specially designed Polypropylene elements for your various sized applications.