High Pressure Series (HP) – Overview

The HP-Series is designed to handle pressures up to 4,569 PSI/315 Bar, typically found in applications such as hydraulics and transmissions. You need more than a good quality oil and standard filter to extend component life and time between oil changes. External contamination arises from many sources including contaminated ‘new unused oil’, airborne particles (dust) and moisture laden air which enters through the breather, cylinder seals, shaft seals, or during maintenance activities. Internal contamination arises when a system ‘self-contaminates’ over time. The main high pressure oil filters are generally rated at 10 µm (human hair = 50 µm, bacteria cells = 2 µm) and have a limited ability to remove water and high volumes of ‘ultra-fine’ particles and wear metals.

The HP-Series is designed to handle pressures up to 4,569 PSI/315 Bar, typically found in applications such as hydraulics and transmissions. You need more than a good quality oil and standard filter to extend component life and time between oil changes. External contamination arises from many sources including contaminated ‘new unused oil’, airborne particles (dust) and moisture laden air which enters through the breather, cylinder seals, shaft seals, or during maintenance activities. Internal contamination arises when a system ‘self-contaminates’ over time. The main high pressure oil filters are generally rated at 10 µm (human hair = 50 µm, bacteria cells = 2 µm) and have a limited ability to remove water and high volumes of ‘ultra-fine’ particles and wear metals.

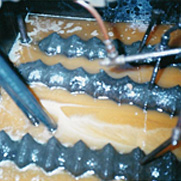

Over time these particles accumulate to create a sandblasting effect through the system. Compounded with the presence of water, and the formation of acids, the system is subjected to accelerated erosion, abrasive wear, adhesive wear, cavitation, fatigue, oxidation, varnishing, gum and sludge formation, decreasing the life and efficiency of the component, creating a catastrophic failure in time. Without the removal of water and ultra-fine contamination, full-flow filters alone cannot keep oil consistently clean.

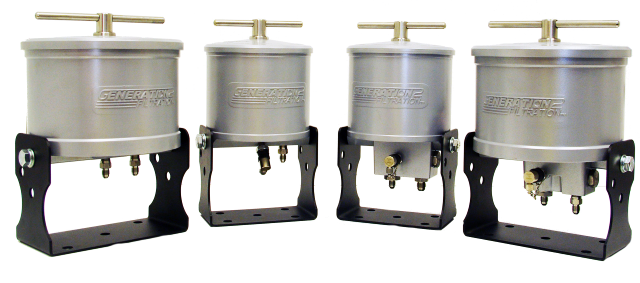

Generation 2 Filtration™ ‘bypass’ filtration has the ability to polish small volumes of oil at low flow rates, down to 1 micron, through the precision wound multi-ply ‘axial-flow’ cellulose element, removing the ultra-fine contamination and water normally missed by standard Filters. With 4 stages of filtration, Generation 2™ elements (ß2 = 200) are designed to meet and exceed ‘Servo Control Valve’ requirements associated with high accuracy and stability, precise positioning, fine velocity and acceleration controls, found in hydraulics and other high pressure applications.

Generation 2 Filtration™ ‘bypass’ filtration has the ability to polish small volumes of oil at low flow rates, down to 1 micron, through the precision wound multi-ply ‘axial-flow’ cellulose element, removing the ultra-fine contamination and water normally missed by standard Filters. With 4 stages of filtration, Generation 2™ elements (ß2 = 200) are designed to meet and exceed ‘Servo Control Valve’ requirements associated with high accuracy and stability, precise positioning, fine velocity and acceleration controls, found in hydraulics and other high pressure applications.

YOU CHANGE YOUR OIL NOT BECAUSE YOU WANT TO…BUT BECAUSE YOU HAVE TO!

UNTIL NOW!