Explanation

Healthy Oil – No Problem

Generation 2™ elements remove water at 99.97% from oil, significantly decreasing the formation of acids, keeping the Total Acid Number (TAN) low, diminishing the accelerated depletion of additives and formation of oxidation, varnish, sludge and gum deposits within the component, dramatically extending the life of the equipment and time between oil changes.

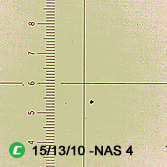

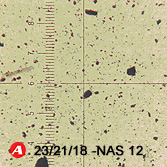

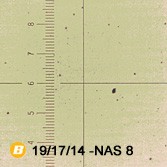

ISO and NAS Cleanliness Codes

Internationally recognized standards are used to quantify the number and size of particles in oil. This chart illustrates both standards, the condition of a typical system, and oil cleanliness levels obtained using G2F.

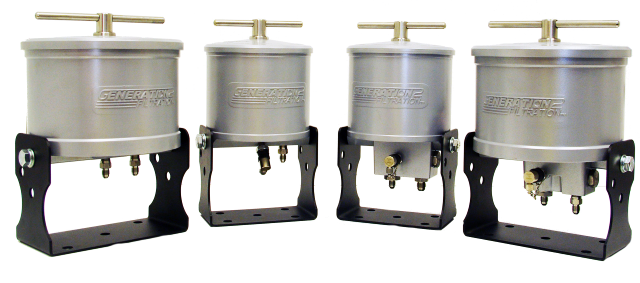

Generation 2 Filtration™

Contaminated Oil

New Unused Oil

![]() Oil operating in this category will shorten the life of hydraulic components & oil, causing premature wear

Oil operating in this category will shorten the life of hydraulic components & oil, causing premature wear

and continuous breakdowns.

![]() Oil operating in this category will extend oil & component life, reducing hydraulic system breakdowns.

Oil operating in this category will extend oil & component life, reducing hydraulic system breakdowns.

Fluid Cleanliness Levels

Manufactures of hydraulic systems establish fluid ISO cleanliness levels to provide maximum life extension of the component. Once cleanliness target valves for any given component are exceeded, the equipment will suffer increased wear and failure rates.

| Component | ISO | NAS |

| Servo control valves | 16/14/11 | 5 |

| Proportional valves | 17/14/12 | 6 |

| Vane and piston pumps/motors | 19/16/13 | 7 |

| Vane and piston pumps/motors | 19/16/13 | 7 |

| Directional and pressure control valves | 19/16/13 | 7 |

| Gear pumps/motors | 19/17/14 | 8 |

| Flow control valves cylinders | 20/18/15 | 9 |

| New unused oil | 19/17/14 | 8 |