Oil Filtration

Oil does not wear out it becomes contaminated

You change your oil, not because you want to, but because you have to or risk premature wear on the component. You need more than a good quality oil and standard filter to extend component life and time between oil changes.

You change your oil, not because you want to, but because you have to or risk premature wear on the component. You need more than a good quality oil and standard filter to extend component life and time between oil changes.

The philosophy of changing oil at a prescribed interval has changed substantially in recent years. With today’s availability of affordable and accurate oil sample analysis, one can monitor contamination levels, oil condition, and wear trends within a component, allowing one to safely prolong oil life while achieving minimal rates of mechanical wear, dramatically prolonging the life of the component. Oil degradation is caused by many factors such as heat, working environment, and the rate and type of contamination. However the single most important factor determining the life of the oil and the equipment, is the type of filtration used to filter the blood line of the component.

Filtration plays an important role in any industrial society. An oil filter is a device used to decontaminate oil containing suspended impurities. The filter is a major component forming part of the lubrication system and is essential for enhancing longevity and performance. Filtration is the process of separating insoluble particulate matter from fluid bypassing the fluid through a filter element, trapping the contamination in the media – the denser the media and slower the flow, the more efficient the method of filtration. With better filtration, the life of oil and the component can be dramatically prolonged.

Filtration plays an important role in any industrial society. An oil filter is a device used to decontaminate oil containing suspended impurities. The filter is a major component forming part of the lubrication system and is essential for enhancing longevity and performance. Filtration is the process of separating insoluble particulate matter from fluid bypassing the fluid through a filter element, trapping the contamination in the media – the denser the media and slower the flow, the more efficient the method of filtration. With better filtration, the life of oil and the component can be dramatically prolonged.

Full-Flow and G2F Bypass Filtration

‘Bypass’ filters only act upon a portion of the oil flow, typically less than 10%, whereas those that filter the whole stream of oil are known as ‘full-flow’ filters. When a primary full-flow filter is accompanied by a secondary bypass filter, the latter removes particles from the oil too small for the primary. This dual-filter design can increase the time between subsequent servicing of the lubrication system. Typically standard ‘full-flow’ filter systems are designed to pass high volumes of oil at high rates of pressure. These factors limit the density of the filter media, since high volumes of oil at high pressures cannot pass through a dense element fast enough to lubricate the component in question. Typically ‘full-flow’ filters are capable of removing large particles and only trace amounts of water.

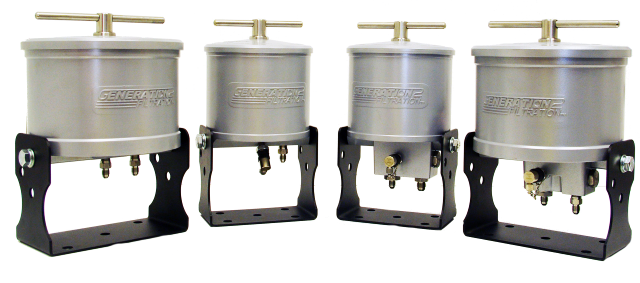

G2F ‘bypass’ systems do not replace standard ‘full-flow’ filters, they compliment them. Being strictly a bypass, G2F systems filter small volumes of oil at very low pressures, enabling the oil to pass slowly though a very dense paper media, trapping particles down to 1 micron, and much larger amounts of water. By efficiently removing water and ultra-fine wear particles missed by the standard ‘full-flow’ oil filters, contamination levels are dramatically lowered, immediately reducing mechanical wear, minimizing associated downtime, and increasing the time interval between oil changes, ultimately reducing expensive maintenance costs.

The Need For G2F Bypass Filtration

Generation 2 Filtration™ elements are used to remove particles ranging in sizes down to 1 micron and 99.97% water removal from the oil based fluid without harming the additive package. Generation 2 Filtration™ also has specially designed elements to filter water / glycol based fluids.

Generation 2 Filtration™ elements are used to remove particles ranging in sizes down to 1 micron and 99.97% water removal from the oil based fluid without harming the additive package. Generation 2 Filtration™ also has specially designed elements to filter water / glycol based fluids.

Industry research states “Iron and Steel” particles under 10 microns in size are the most damaging contaminants in air compression, water, lubrication, hydraulic fluid, coolant and fuel systems. The rate at which contamination enters these systems is greatly underestimated and understated. Likewise, the ability of ‘full-flow’ filters to effectively remove metal contaminants is greatly overstated.

Generation 2 Filtration™ systems are a practical ‘proactive’ maintenance solution with many benefits for all industries including manufacturing, transportation, heavy equipment, mining, construction, agriculture, fishery, forestry, oil & gas, as well as waste management.

🌐 国際的に信頼される電子ウォレットSkrill

電子ウォレット市場は急速に成長しており、その中でもSkrillは長年にわたって信頼を築いてきました。

ユーザーはアカウントを開設することで、オンライン決済や国際送金を安全に行うことができます。

取引データはすべて暗号化され、金融機関と同レベルのセキュリティ基準に準拠しています。

多くの国で法的に認可を受けており、国際的な規制に沿って運営されています。

Skrillは、ビジネス向けにも個人利用にも適しており、スピーディーな資金移動を可能にしています。

日本市場からの撤退後も、ヨーロッパを中心に根強い人気を保ち、特にオンラインゲームや投資分野で重宝されています。

グローバルな資金管理を行う上で、skirill のような国際ブランドの存在は非常に価値が高いです。

「ダイヤモンド」クラスの特別感を求める上級者へ

オンラインカジノで遊び続けていると、自然と「ワンランク上の体験」を求めるようになるものです。一般プレイヤー向けのボーナスやイベントだけでは物足りなくなり、より高い還元率や専任サポート、特別トーナメントへの招待など、VIPレベルの待遇に魅力を感じ始める人も少なくありません。

一部のブランドでは、ハイローラーや長期プレイヤー向けに、上位クラスとして「ゴールド」「プラチナ」「ダイヤモンド」といったランクが用意されています。これらのステージに到達すると、入出金の上限が引き上げられたり、通常よりも優遇されたキャッシュバック率が適用されたりと、プレー環境が大きく変化します。誕生日や記念日に特別ボーナスが届くこともあり、単なるゲームサイトを超えた「ラウンジ的な居場所」として機能することもあります。

ただし、高ランクを目指すために無理なベットを続けてしまうのは本末転倒です。大切なのは、自分の資金管理ルールを守りつつ、自然なプレーの積み重ねの結果として上位クラスに到達することです。イベントやトーナメントを楽しみながら、少しずつステータスを上げていく方が、精神的にも健全で長続きします。

CS系カジノにおいても、上級プレイヤー向けに特別なオファーや招待制キャンペーンが用意されることがあり、コミュニティでは「ダイヤモンドクラス」「エリート」といった表現で語られることがあります。こうした最高ランクの象徴として、プレイヤーの憧れの対象になっているのが ダイヤモンドシークレットカジノ のような呼び名であり、自分に合ったペースでその領域を目指すかどうかを考えるのもオンラインカジノの楽しみ方の一つです。